INFINAIR LEAN FOR YOU——SMED: Flexible batch quantity

2015-08-16

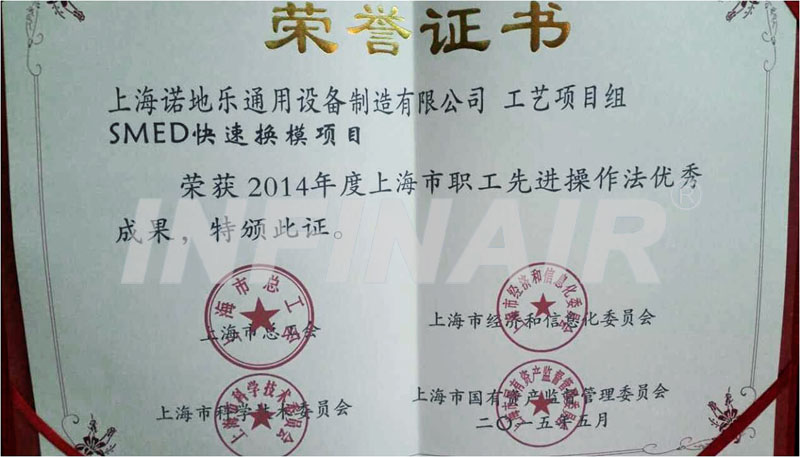

INFINAIR SMED project has been awarded in 2015 by local city municipal authorities. It is not only an award to the people in INFINAIR, but also means something to you.

What is SMED?

Single-Minute Exchange of Die (SMED) is one of the many lean production methods for reducing waste in a manufacturing process. It provides a rapid and efficient way of converting a manufacturing process from running the current product to running the next product. This rapid changeover is key to reducing production lot sizes and thereby improving flow. The concept arose in the late 1950s and early 1960s, when Shigeo Shingo was consulting to a variety of companies including Toyota, and was contemplating their inability to eliminate bottlenecks at car body-molding presses.

What has INFINAIR done?

The bottlenecks in INFINAIR were long hydraulic drawing dies changeover time, which drove up production lot sizes. The change-over takes a long time, and then, the lost production due to change-overs drives up the cost of the actual production itself. INFINAIR's additional problem was that land costs in Shanghai, as well as the fund interest in China, are very high and therefore it was very expensive to store our fans. This means we must reduce our cost, which are higher than other producers, thus we had to produce fans in economic lots.

The economic lot size is carefully calculated from the ratio of actual production time and the 'change-over' time in the INFINAIR workshop. It is the time taken to stop production of a product, such as a wind cap for an aluminum roof fan, and start production of the same, or another type of fan. More importantly, we took video of the whole process, and then, frame by frame, figured our what are unnecessary steps that should be removed. Moreover, the smart workers formed a team, discussed together, and worked out a solution to realize this. Action taken includes reworking on the drawing machines, vehicle to carry the molds, and utilize methods/ common tooling to quickly switch molds from one to another.

Thus, in 2015, the INFINAIR SMED project was awarded The Honor of Year 2014 Shanghai Workers’ Advanced Operation Methods, which are co-organized by Shanghai Federation of Trade Unions, Shanghai Science and Technology Commission, Shanghai Municipal Economic and Information Technology Commission, and Shanghai State-owned Assets Supervision and Administration Commission.

What is SMED?

Single-Minute Exchange of Die (SMED) is one of the many lean production methods for reducing waste in a manufacturing process. It provides a rapid and efficient way of converting a manufacturing process from running the current product to running the next product. This rapid changeover is key to reducing production lot sizes and thereby improving flow. The concept arose in the late 1950s and early 1960s, when Shigeo Shingo was consulting to a variety of companies including Toyota, and was contemplating their inability to eliminate bottlenecks at car body-molding presses.

What has INFINAIR done?

The bottlenecks in INFINAIR were long hydraulic drawing dies changeover time, which drove up production lot sizes. The change-over takes a long time, and then, the lost production due to change-overs drives up the cost of the actual production itself. INFINAIR's additional problem was that land costs in Shanghai, as well as the fund interest in China, are very high and therefore it was very expensive to store our fans. This means we must reduce our cost, which are higher than other producers, thus we had to produce fans in economic lots.

The economic lot size is carefully calculated from the ratio of actual production time and the 'change-over' time in the INFINAIR workshop. It is the time taken to stop production of a product, such as a wind cap for an aluminum roof fan, and start production of the same, or another type of fan. More importantly, we took video of the whole process, and then, frame by frame, figured our what are unnecessary steps that should be removed. Moreover, the smart workers formed a team, discussed together, and worked out a solution to realize this. Action taken includes reworking on the drawing machines, vehicle to carry the molds, and utilize methods/ common tooling to quickly switch molds from one to another.

Thus, in 2015, the INFINAIR SMED project was awarded The Honor of Year 2014 Shanghai Workers’ Advanced Operation Methods, which are co-organized by Shanghai Federation of Trade Unions, Shanghai Science and Technology Commission, Shanghai Municipal Economic and Information Technology Commission, and Shanghai State-owned Assets Supervision and Administration Commission.